Why You Need Stretch Wrapper Repair Service: Discovering Its Role in Ensuring Packaging Top Quality and Safety And Security

Stretch wrappers play a necessary role in the product packaging procedure by guaranteeing the security and stability of packed products. They can run into numerous problems that necessitate prompt repair work. Disregarding these repair work can cause considerable inadequacies and potential item damage. Recognizing the implications of stretch wrapper upkeep is vital for any kind of business. This conversation will explore exactly how routine repairs add to product packaging high quality and safety, ultimately impacting the whole supply chain.

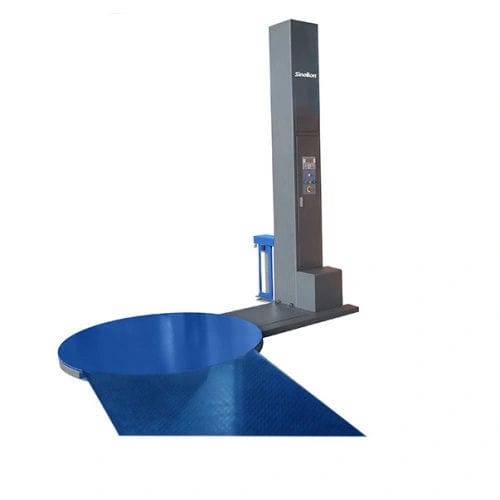

Recognizing the Value of Stretch Wrappers in Packaging

Although commonly overlooked, stretch wrappers play a crucial function in the packaging process for numerous markets. These makers ensure the safe bundling of products, improving security and protecting products during transport. By firmly covering products in stretch movie, they reduce the risk of damage from changing or environmental factors.In markets like food, drugs, and production, effective packaging is critical for keeping product honesty and safety (stretch wrapper repair). Stretch wrappers contribute to this by reducing the probability of contamination and perishing, thus extending service life. Furthermore, their performance advertises cost-effectiveness; businesses can simplify product packaging procedures, minimizing labor costs and time.Moreover, stretch wrappers can suit different item shapes and sizes, making them functional devices in packaging. Their ability to adapt different loads ensures that also irregularly designed things are secured correctly. To summarize, the significance of stretch wrappers can not be underestimated in the pursuit for high quality packaging services

Typical Issues That Necessitate Stretch Wrapper Repair Service

Stretch wrappers, while crucial for maintaining product packaging honesty, can experience various functional issues that demand repair work. Typical problems consist of irregular tension, which might lead to broken or loosened loads, compromising product protection throughout transport. Additionally, malfunctioning sensors can disrupt the wrapping procedure, resulting in unequal application of stretch film. Worn-out rollers or belts may create slippage, hindering the wrapper's effectiveness and creating hold-ups in production. Issues with the control system can lead to improper settings, impacting the overall covering high quality. Dust and debris buildup in mechanical parts can also bring about tear and wear, necessitating regular maintenance to stop breakdowns. Determining these issues early is essential, as timely fixings can considerably extend the lifespan of the stretch wrapper and keep excellent product packaging requirements. Dealing with these usual problems assurances that businesses can remain to run smoothly and deliver products safely.

The Effect of Disregarding Fixings on Packaging Efficiency

Enhancing Item Safety Through Regular Upkeep

Normal upkeep of stretch wrappers is crucial for avoiding packaging failures that can jeopardize product safety. By attending to wear and tear immediately, firms can considerably reduce item damages and guarantee that devices runs continually. This positive technique not only safeguards the stability of the products but likewise improves general functional effectiveness.

Avoiding Packaging Failings

Efficient upkeep of packaging equipment is crucial for avoiding failures that can jeopardize product safety and security. Normal evaluations and prompt fixings of stretch wrappers assist recognize prospective problems before they rise into considerable problems. When stretch wrappers are well-maintained, they function at peak performance, making sure that products are firmly wrapped and shielded throughout storage and transport. Preventative upkeep schedules can significantly decrease the possibility of mechanical failings, which commonly result in product packaging mistakes or breakdowns. By spending in regular checks, companies not just safeguard their items but also improve their overall functional efficiency. This aggressive method minimizes downtime and promotes a society of safety, ultimately contributing to greater client fulfillment and depend on in the brand. Regular upkeep is as a result a foundation of effective packaging administration.

Lowering Product Damages

Preserving stretch wrappers is crucial for minimizing product damage and making sure safety during handling and transport. Normal maintenance of these makers helps identify and correct minor issues prior to they escalate into substantial troubles, therefore preserving the stability of the wrapped products. When stretch wrappers operate at peak efficiency, they supply constant tension and coverage, which minimizes the danger of lots moving throughout transit. stretch wrapper repair. This reliability avoids possible problems that can develop from inappropriate covering strategies, such as tearing or crushing of product packaging materials. In addition, well-kept stretch wrappers add to a more secure workplace by minimizing the chance of mishaps triggered by unsteady or inadequately wrapped loads. Inevitably, persistent upkeep plays a crucial function in securing both items and personnel throughout the supply chain

Guaranteeing Regular Efficiency

Consistent efficiency of stretch wrappers is essential for enhancing item safety and security throughout the supply chain. Regular upkeep plays an essential function in making certain that stretch wrappers operate effectively, minimizing the likelihood of equipment failings that can compromise product packaging honesty. By routinely evaluating and servicing these devices, companies can recognize potential problems prior to they intensify, thus decreasing downtime and preventing product damage. Additionally, well-kept stretch wrappers use uniform stress to packaging materials, guaranteeing that lots continue to be secure during transport. original site This integrity not just safeguards items from falling or changing however also promotes consumer count on in the brand. Inevitably, prioritizing regular performance through routine maintenance safeguards item high quality and boosts safety for both manufacturers and consumers alike.

Cost-Benefit Evaluation of Buying Repair Work Services

Purchasing fixing services for stretch wrappers can result in substantial long-term cost savings by prolonging equipment life expectancy and lowering the demand for expensive replacements. Furthermore, prompt fixings assist avoid equipment downtime, making certain constant manufacturing circulation. Enhanced product packaging performance even more adds to total functional effectiveness, making repair services a strategic factor to consider for companies.

Long-Term Financial Savings Potential

Reviewing the lasting financial savings capacity of stretch wrapper fixing services discloses considerable expense advantages for services. By purchasing timely repairs, business can prolong the life expectancy of their tools, lowering the frequency of expensive substitutes. In addition, efficient stretch wrappers lessen material waste and warranty constant product high quality, which in turn improves client fulfillment and reduces returns.Moreover, a well-maintained stretch wrapper can cause lower energy intake and reduced operational prices. Repair services often feature service warranties that protect against future expenses, supplying added financial protection. Overall, the positive strategy of spending in repair solutions equates into not only boosted productivity yet additionally significant savings over time, making it a tactical financial decision for organizations intending for sustainability and performance.

Preventing Equipment Downtime

Prompt repair work to stretch wrappers can substantially decrease equipment downtime, an element that directly affects operational effectiveness and earnings. When stretch wrappers malfunction, manufacturing lines can halt, causing hold-ups in satisfying orders and potential loss of revenue. Spending in repair work solutions assurances that tools remains in optimal functioning problem, decreasing the threat of unanticipated malfunctions. This proactive technique not just conserves money in the long run but likewise improves workforce morale, as workers can work without the irritation of malfunctioning devices. Furthermore, maintaining consistent procedures enhances consumer contentment through dependable distribution times. Inevitably, the cost-benefit analysis of purchasing fixing solutions highlights the value of stopping downtime, as it cultivates an extra steady and effective workplace.

Improved Packaging Performance

A substantial improvement in product packaging effectiveness can be achieved via the effective repair of stretch wrappers. Properly maintained stretch wrappers optimize product usage, minimize waste, and warranty regular application of protective movie. stretch wrapper repair. By buying repair services, firms can lengthen the life of their equipment, lessening the requirement for costly replacements. This aggressive technique not just maintains efficiency however also decreases labor prices related to hands-on re-wrapping or harmed pallets. Furthermore, enhanced tools performance can bring about faster product packaging cycles, enhancing overall throughput. Ultimately, the cost-benefit analysis reveals that spending in stretch wrapper fixing services yields significant returns by enhancing functional effectiveness, securing product integrity, and ensuring that product packaging procedures straighten with industry criteria for top quality and security

Choosing the Right Provider for Stretch Wrapper Services

How can one ensure that the chosen solution provider for stretch wrapper fixings meets both quality and effectiveness criteria? Choosing the right service supplier requires cautious factor to consider of a number of elements. Assessing the company's experience and competence in stretch wrapper repairs is vital. A well-established company with a tried and tested performance history can provide assurance of their capabilities. Furthermore, getting referrals or testimonials from previous customers can offer understandings right into the copyright's dependability and service quality.Furthermore, assessing the series of services supplied is required. A detailed repair solution that includes diagnostics, upkeep, and components substitute can facilitate extra effective operations. It's likewise recommended to make inquiries regarding the provider's response time and accessibility for emergency situation repairs, as downtime can significantly impact productivity. Lastly, evaluating cost-effectiveness without compromising quality will aid in making an educated choice that aligns with operational demands and budget restrictions.

Best Practices for Keeping Your Stretch Wrapper Devices

Maintaining stretch wrapper equipment is necessary for assuring peak efficiency and longevity. Routine evaluations should be performed to determine any type of signs of wear or damages, specifically in critical parts such as the film carriage, rollers, and electric motors. Maintaining the equipment clean and complimentary from particles is important, as dust can bring about mechanical failures and inconsistent wrapping results. Oiling moving components according to the supplier's standards will boost performance and minimize rubbing. Furthermore, operators need to be trained to use the equipment effectively, as incorrect usage can cause early wear. It is a good idea to establish go to website a routine maintenance schedule, consisting of look for electric connections and software application updates. Finally, maintaining an appropriate supply of replacement components handy can stop downtime during unanticipated fixings. By adhering to these best methods, business can guarantee their stretch wrappers run efficiently and add to total packaging high quality and safety and security.

Regularly Asked Concerns

Exactly how Usually Should I Set Up Stretch Wrapper Upkeep?

Normal maintenance for stretch wrappers must be scheduled every six months. Boosted usage or specific operational demands may demand extra regular checks to assure peak efficiency and stop unexpected malfunctions, enhancing general performance.

Can I Repair a Stretch Wrapper Myself?

Fixing a stretch wrapper individually is possible, but it requires technical understanding and know-how. Mistakes read the full info here can bring about further damages, so getting in touch with a professional or describing the producer's guidelines is commonly advised for reliable repair work.

What Are the Signs My Stretch Wrapper Needs Repair Work?

Indications that a stretch wrapper needs fixing include irregular wrapping stress, visible damage to the film, uncommon noises during procedure, regular jams, and failing to correctly secure lots. Prompt interest is crucial to maintain efficiency and safety and security.

For how long Does a Regular Stretch Wrapper Repair Take?

The period of a typical stretch wrapper fixing varies, often taking in between one to three hours, depending on the intricacy of the problem. Aspects such as parts availability and specialist expertise likewise affect fixing time.

Exist Warranties for Stretch Wrapper Repair Service Services?

Service warranties for stretch wrapper repair work solutions frequently differ by provider. Generally, respectable firms supply restricted service warranties covering parts and labor, ensuring clients get reputable solution and defense against flaws or concerns emerging post-repair. Stretch wrappers, while important for maintaining product packaging stability, can run into numerous operational issues that demand repair work. Determining these problems early on is essential, as timely repair work can greatly prolong the life-span of the stretch wrapper and keep excellent packaging standards. Spending in repair service solutions for stretch wrappers can lead to significant long-lasting financial savings by expanding tools life-span and lowering the need for pricey replacements. Furthermore, effective stretch wrappers reduce material waste and guarantee regular item quality, which in turn enhances client contentment and minimizes returns.Moreover, a well-kept stretch wrapper can lead to lower energy consumption and decreased functional prices. A significant improvement in packaging performance can be accomplished via the reliable repair work of stretch wrappers.